Industrial Products

- Electromagnetic Flow Meter

- Mechanical Flow Meter

- Level Indicators

Fire & Safety

- Stationary Fire & Safety

- Hydrant Management

Baffle plate flow meters

Robust and flexible – Suitable for any flow direction

MECON can rely on decades of experience in production of mechanical flow meters in robust full-metal versions. Our baffle plate flow meters are suitable for high temperatures of up to +250 °C – irrespective of the direction of flow. The products also impress with easy installation, numerous connection options and electrical outputs.

Baffle plate flow meters by MECON

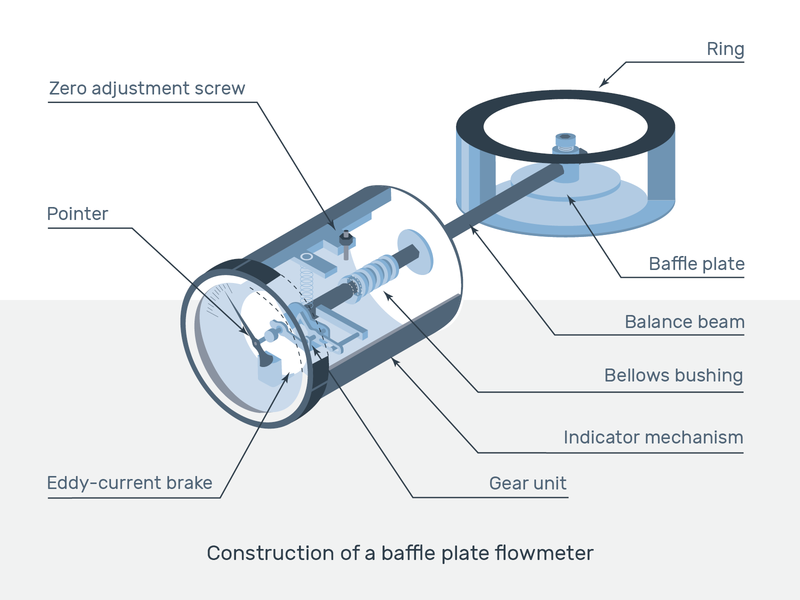

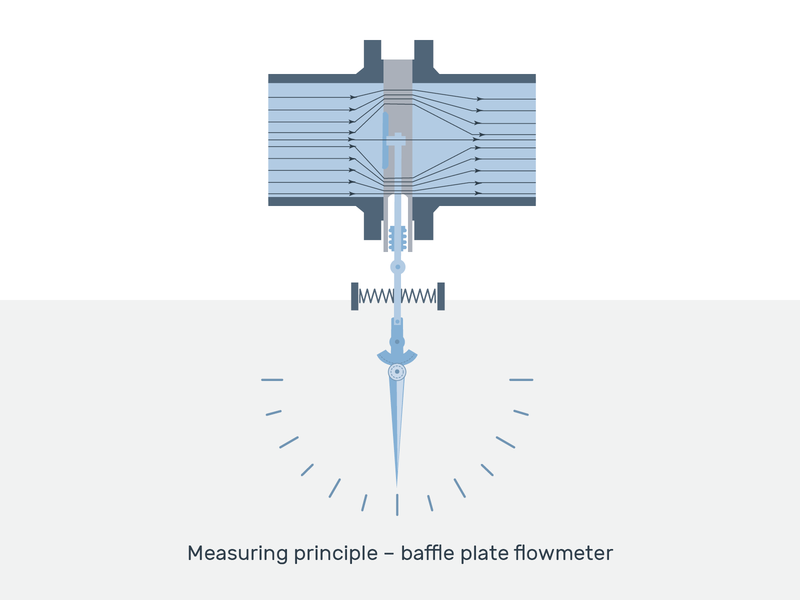

Measurement principle and structure for baffle plate flow meters

Baffle plate flow meters work based on the deflection method principle (see Fig. 1). Accordingly, the flow meter consists of a baffle plate (b) with a scale beam (c), which transfers the stasis of the measured media by routing it through the bellows (d) to the indicator (e). At the same time, a rack and pinion drive (f) converts the resulting deflection into a rotary motion (h). The indicator motion is regulated by an eddy current brake (g).

Advantages of baffle plate flow meter:

- Product scale for liquids and gases

- Simple installation due to sandwich construction

- Solid design

- Suitable for any flow directions

- Can be equipped with a limit contact and potentiometer (optional)

Measurement tasks and measurable media of baffle plate flow meters

Baffle plate flow meters are ideal anywhere a robust and reliable flow meter is required in plant engineering to measure water, liquids, corrosion protection and lubricants, solvents, saturated and overheated steam and industrial gases.

MECON meters are used in a wide range of industries worldwide:

- Chemicals

- Building services equipment, air conditioning, heating

- Oil and gas