Industrial Products

- Electromagnetic Flow Meter

- Mechanical Flow Meter

- Level Indicators

Fire & Safety

- Stationary Fire & Safety

- Hydrant Management

Float-type flow meters

Reliable and durable solutions for metering liquids and gases

MECON has been developing advanced solutions for industrial flow metering technology for decades. Our float-type flow meters are among the key technological modules and impress with their great reliability and long service lives. As a result, they can be used flexibly for measuring liquids and gases in a range of industries.

MECON provides precise measuring cones made of glass, plastic and metal for float-type flow metres. For certain devices, MECON can also supply the corresponding limit contacts and electric potentiometers.

Float-type flow meter

Measurement principle for float-type flow meter

When Rota introduced industrially-produced rotating floats to the market in 1908, the term “float-type flow meter” established itself as the technical term for this type of mechanical flow meter. Engineer Karl Küppers from Aachen registered a patent in the same year. Since then, “Rotameter” or “Rotamesser” remain the standard specialised terms in the industry for float-type flow meters.

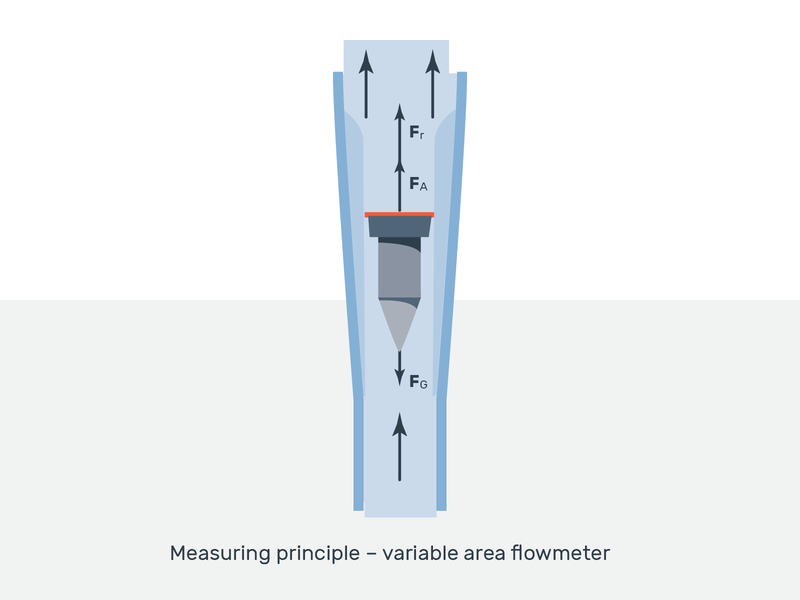

Flow meters which operate on the float principle work via a vertically standing conical measurement tube made of glass, metal or plastic. The specially designed float can move up and down freely in it. Accordingly, the flow values can be read on the Rotameter scale at the height of the measurement edge of the float.

The meter is installed vertically in the piping system, so that the medium must flow from the bottom up. When the medium flows through the conical body of the meter, a float moves internally on the vertical axis. Due to its deadweight, the float always sinks to the opening of the meter (inlet side).

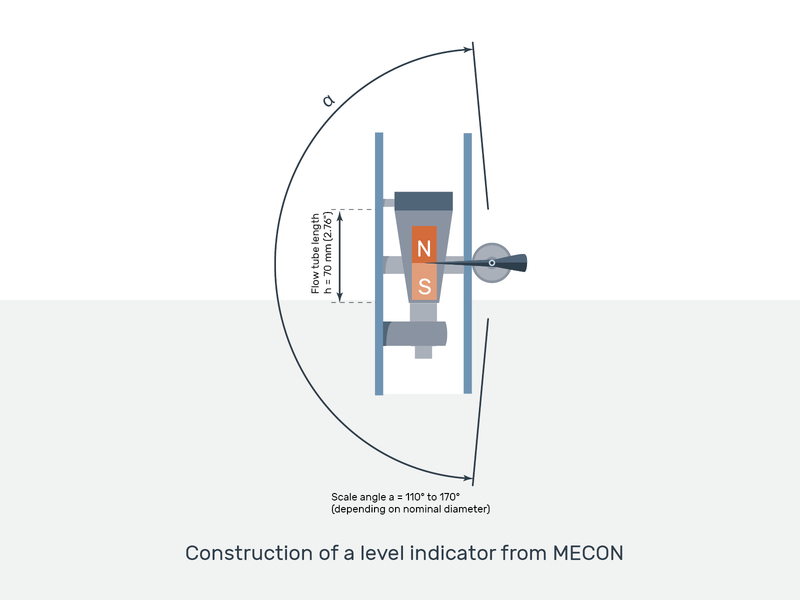

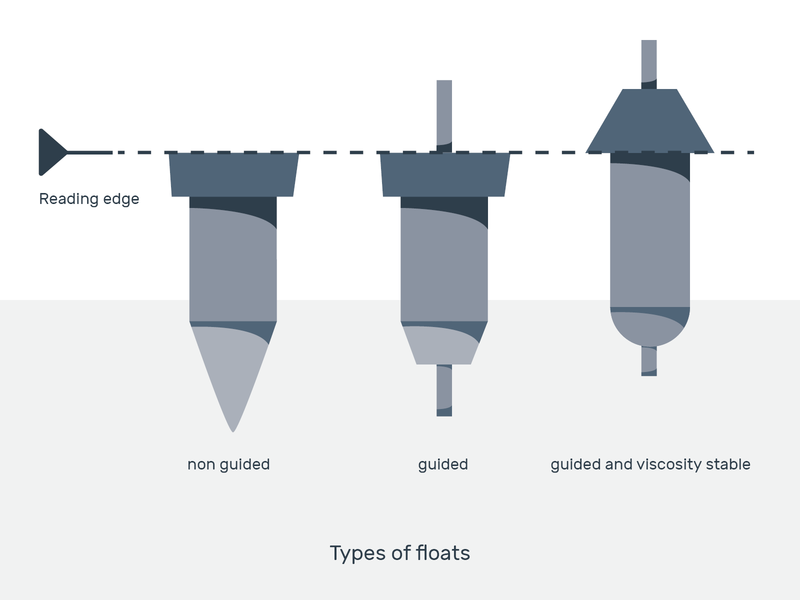

The pressurised medium in the piping system (lift force FA) causes the float to rise as soon as the deadweight is reached in the measuring cone (weight force FG). Due to the conical form, the meter gets wider towards the top. So the more the float is lifted upwards, the more of the medium to be measured can flow past it (flow resistance FR). Due to balanced forces, the float evens out at a certain measurement value. This measurement maps the flow speed and is read on the scale in l/h at the upper edge of the float. (see fig. Types of floats) Types of floats As the volume flow decreases, the float sinks again and the measurement changes accordingly.

Structure of float-type flow meters

A complete flow meter consists of a mag-flux M1 measuring transducer for synchronised d.c. fields and a corresponding sensor (flow sensor). All mag-flux product family MID are available as synchronised d.c. field systems (DC) and are extremely robust and resistant to interference in operation, as there are no moving parts. The special design also avoids pressure losses due to the measurement technology. For individual custom solutions, we recommend using a.c. field devices.

The sensors, when combined with our measuring transducer mag-flux M1 can achieve a measurement accuracy of more than ±0.5% via precise wet calibration of the devices.

Product versions of the mechanical float-type flow meter

Plastic:

- Short lead time

- Low-cost version

Glass:

- High dimensional accuracy

- Can be used for temperatures up to +150 °C

- High repeat accuracy

Metal:

- Robust full-metal fitting version

- Can be used for temperatures up to +350 °C

- Pressure up to 400 bar

Advantages of our magnetic-inductive flow meter (MID):

- The measurement principle does not depend on pressure, density, temperature and viscosity

- No moving parts = No wear

- Pressure losses are avoided via the special design

- Analogue output signal

- Also suitable for aggressive and corrosive media

- Reliability (long-term stability, service life)

- Minimum maintenance requirements

- Simple interpretation of measurement values

- Easy commissioning

- High measurement accuracy

- Wide range of cladding materials for drinking water, waste water, chemicals and solids

- Abrasion and corrosion-resistant claddings available

Float-type flow meter, plastic or glass

Can be displayed directly on the scale located directly on the measuring cone (e.g. in l/h). The reading edge is at the largest diameter of the float body.

Metal float-type flow meters

Recording and testing the linear/non-linear mass or volume flow quantities of a liquid or gas are the main measurement tasks of a float-type flow meter. A range of factors must be taken into account when choosing them:

- Type of media to be measured

- Pressure and temperature ranges of the medium

- Accuracy and measurement rate required for measurement

MECON offers you an extensive selection of float-type flow meters - always perfectly tailored for the respective measuring task and offering the economically optimal product solution.

MECON meters are used in a wide range of industries worldwide:

- Plant and mechanical engineering

- Construction machinery and equipment

- Chemicals

- Building services equipment

- Laboratory apparatus

- Food

- Metal extraction, production and processing

- Oil and gas

- Shipping

- Water and wastewater